Fruit CA cold storage project

1、 Project background

With the improvement of people’s living standards, people’s demand for fresh fruits is becoming more and more particular, especially in some large and medium-sized cities, the off-season consumption of fruits is becoming increasingly common. In order to solve the contradiction between seasonal production and consumption demand of fruits, it is necessary to find a new storage way to store fruits in large quantities and for a long time without losing the original delicious flavor and nutrition; The emergence of modified atmosphere storage provides a scientific method and means to solve the problem of long-term storage.

The controlled atmosphere storage fresh-keeping storehouse can automatically balance the oxygen and carbon dioxide content in the storehouse, remove ethylene gas (ripening hormone), and control the temperature and humidity in the storehouse to achieve the purpose of fresh-keeping. Its main features are as follows:

According to the above advantages of modified atmosphere storage and fresh-keeping storehouse, combined with the current situation and prospects of fruit production in * * * * market and the needs of enriching the life taste of urban residents, it also provides a strong backing for fruit farmers to improve quality and yield, increase efficiency and increase income, and effectively improve the enthusiasm of forest and fruit industry production, so it is proposed to build a modified atmosphere fresh-keeping storehouse.

2、 Construction scale and product scheme construction scale:

In order to solve the problem of fresh-keeping and storage of real estate, famous and special fruits, especially the practical problem that fruit farmers increase production without increasing income, the local fruit market presents the current situation of oversupply, expand the real estate fruit market and improve the competitiveness of the real estate fruit market, increase the added value of products and the income of fruit farmers, increase the supply of fresh fruits in winter, and improve the living standards of urban residents, group plans to be in * * * * City, * * * * province, It is located in the development zone of * to build a controlled atmosphere storage and fresh-keeping warehouse with a certain scale. The fresh-keeping and storage products of this project are mainly high-quality fruits produced by ourselves around * * * * City, * * * * province. According to the investigation and Research on the production and sales market of products and in combination with the local fruit industry development plan, the planned reserve of the modified atmosphere fresh-keeping warehouse of this project is 5000 tons, and the total area of the fruit fresh-keeping warehouse is 7398 square meters. According to the plan, the construction is ready to start at the end of * in 2022, and the planned construction period is one year.

3、 Project design overview

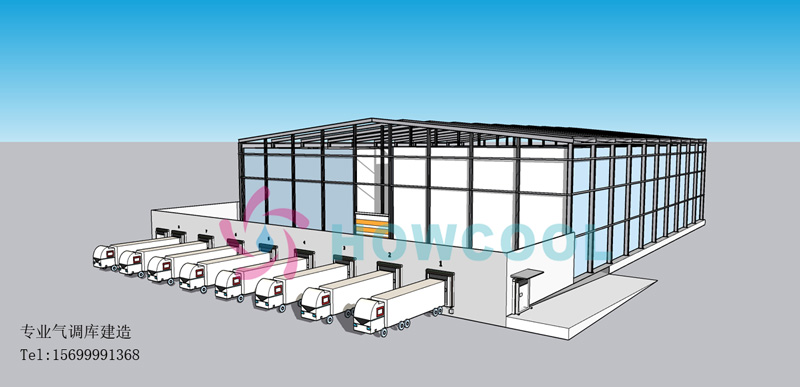

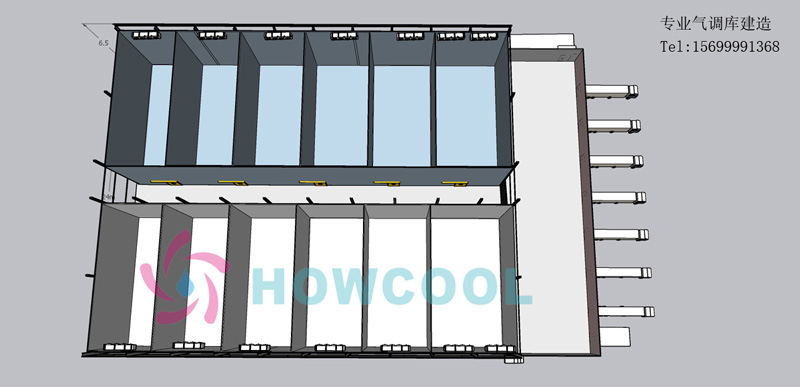

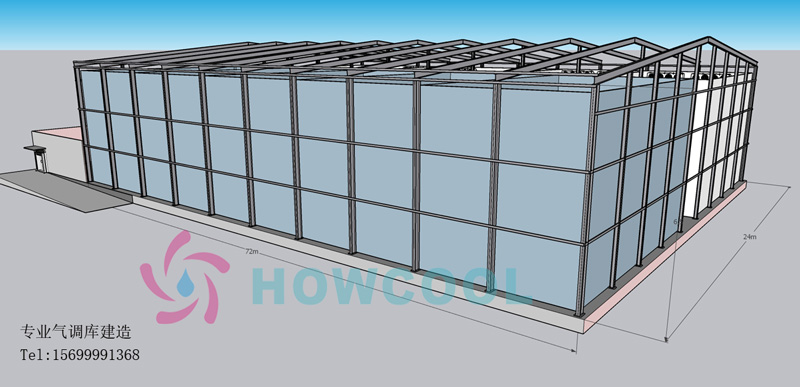

3.1 plan of reservoir body

There are 16 controlled atmosphere fresh-keeping cold storages in this warehouse. The size of the warehouse is about -2 ℃ with the lowest temperature. The storage is mainly fruits, with different varieties and vegetables.

<1> Known conditions

Net size in cold storage: (length x width x height 6500)

Net area in cold storage: 7398 square meters

Net volume in cold storage: 27000 cubic meters

Maximum inventory: 5000T

Kuwen: + 5℃~-2℃ (Te=-10℃,Tc=+45℃)

Storage: Fruits and vegetables

Daily throughput: 100T/d

Incoming temperature: + 25℃,

Insulation of reservoir: Polyurethane double-sided color steel cold storage board, PIR thickness 100mm

Control mode: fully automatic

Condensation method: Air cooled condensation + evaporative condensation

Refrigerant: r507

A normal temperature buffer room is set at one side of the door of the 16 cold storages, and a loading platform should be equipped outside the buffer room. An equipment room (machine room) is set in the middle of the platform. The refrigeration compressor unit and air conditioning equipment in this area are installed in the equipment room (machine room), and the condenser is placed outside the wall of the equipment room or on the roof of the equipment room.

3.2 refrigeration equipment

<1> Refrigeration compressor unit

According to the cooling capacity demand of the warehouse of the project, bizel multi head parallel semi closed / screw / piston refrigeration compressor unit is designed as the refrigeration host, and the number of units is 2. The refrigeration mode is mechanical refrigeration direct expansion type and fully automatic PLC control.

Its advantage is that it can automatically adjust the energy according to the change of purchase quantity, so as to save energy. At the same time, it has the function of mutual standby, reducing the installed capacity. The condensing method adopts air-cooled condenser, which aims to facilitate maintenance, simplify the system, and reduce the cost of daily maintenance.

The compressor unit is arranged in the machine room to ensure that the equipment spacing and sufficient access inspection spacing, the main channel is not less than 1.5m, and the equipment spacing is not less than 0.7m.

In order to improve the utilization efficiency of machinery, considering the management, maintenance, efficient operation of equipment and energy conservation, the refrigeration unit adopts parallel piston / screw unit, and the refrigerant adopts r507.

<2> Calculation of cooling capacity

calculation of cooling consumption of 16 CA reservoirs in the first reservoir area:

(1) Calculated cooling capacity of each -2 ℃ controlled atmosphere storage: * * * * kw

(2) Calculated cooling consumption of 16 controlled atmosphere storages: kw

(3) The platform area shall be equipped with cooling source according to the total cooling consumption: 80%, and the refrigerating capacity of the refrigerator shall not be less than: kW

The daily incoming volume of a single room is 100 tons, the incoming temperature is 25 ℃, and it drops to -2 ℃ in 24 hours.

<3> Unit selection:

Optional equipment for -2 ℃ controlled atmosphere storage in the storage section:

compressor unit selection: * type air-cooled condensing parallel unit (2 sets)

the unit is equipped with a Bezier piston compressor unit.

cooling capacity of single compressor: kw (evaporation temperature: -10 ℃, condensation temperature: cooling capacity at 45 ℃,)

total cooling capacity: kW, = meet the cooling capacity demand.

unit operating power: kW, Condenser fan power: kW,

(when the condensing fan works at full load)

each silo is equipped with a type of suspended air cooler between silos, with a total operating power of:

0.55x3x = kW, (1 set of 4 fans)

cooling fan is equipped with cooling ton external balance thermal expansion valve, pieces (r507), each warehouse

3 control cabinets

the condenser adopts a type of top outlet air-cooled condenser, with a heat exchange capacity of about kW, meeting the heat dissipation requirements of the unit.

Overview of electric control system design for cold storage

The integrated control system consists of the following main parts

1、 PLC control system:

German Siemens S7 Series products are selected. This part is responsible for the control of the main equipment of the cold storage. Because PLC has unparalleled stability, all the core control logic is completed by it. The temperature and operating conditions of each storage are displayed through the PLC touch screen, and the equipment operation data is displayed through the touch screen.

2、 Touch screen (on-site human-machine interface)

The touch screen, with an all English interface, can display the operation status, temperature, humidity, oxygen content, nitrogen content and carbon dioxide content of each cold storage in real time, and can modify and monitor the relevant parameter settings on site and remotely.

3、 Temperature sensor transmitter uses * * * * temperature sensor

electric defrosting is adopted for defrosting in cold storage

control the defrosting of each cold storage one by one according to the accumulated working time of the cold storage collected by PLC

note: see the description and quotation for the configuration of air conditioning equipment.

Advantages of Bitzer parallel unit:

the refrigerating capacity is larger than that of general refrigerating units.

the compressor is manufactured by Bezier China.

safe and efficient, it is the best choice to replace the large ammonia refrigeration unit.

automatic energy regulation, such as: 33% – 66% – 100% for multi head parallel units

Energy regulation, adapt to load changes and save energy.

It can fully meet the requirements of load change and energy conservation, and can facilitate energy regulation to achieve the best energy-saving effect. It can be best matched at any time and on any occasion. It is always the most suitable solution, saving electricity by 30% – 50%.

evenly distribute the cooling load through the refrigeration system, improve the reliability and prolong the service life.

the floor area is small, multiple compressors share the frame, and the system layout is simple and compact, saving space.

the controller adopts computer precise control and imported control elements, with low failure frequency.

Bitzer parallel unit adopts the principle of customized design, and the production is customer-oriented, which is really your own unit.

Bitzer parallel unit can be repaired without affecting the use, reducing abnormal downtime and maintenance costs.

adopt reliable oil return assurance devices (oil distributor, equalizing oil pipe, oil level regulator, oil storage tank, etc.), negative pressure oil pump, accurate lubrication, and ensure reliable operation.

the integrated computer automatically controls the machine operation to realize balanced use, which is energy-saving and convenient.

The condensing pressure of the condenser has the function of automatic adjustment, which can be used normally in winter and summer, and is not affected by seasonal changes.

it can realize separate zone defrosting, and the refrigeration and defrosting of each branch do not affect each other, so as to ensure that the refrigeration space and goods are always at a suitable temperature.

Air cooled condensing system

The air-cooled condensation system has low condensation temperature and high refrigeration efficiency. It is easy to use and maintain. Performance introduction of ceiling cooling fan

The fluorine cooling fan applies the new technology of copper tube and wave deflector to strengthen the aluminum alloy fin, hydraulic expansion tube, copper tube and aluminum sheet

It can connect energy closely and greatly improve the thermal conductivity. It is specially developed to adapt to freon refrigerant. It has the characteristics of compact structure, smaller volume, better thermal conductivity, uniform air supply and easier frost flushing (the picture is for reference only, subject to the real object).

The following details the design:

(1) Evaporator design

Large sleeve expansion tube design: adopt large tube capacity thick wall copper tube, and the whole large sleeve of aluminum alloy (thickness 0.2mm)

By hydraulic expansion, the large sleeve is in close contact with the base pipe, which can greatly increase the heat conduction effect.

Blade spacing design: different fin spacing shall be adopted for different frosting conditions in the warehouse to ensure high refrigeration efficiency, effectively increase the defrosting interval and reduce the temperature fluctuation caused by defrosting.

Design results: due to the cross arrangement between the tubes, the heat exchange time between the air and the finned tubes is prolonged, and the heat transfer efficiency is improved. At the same time, in order to reduce the resistance of the finned tubes, the method of thinning the thickness of the evaporator is adopted, which also produces a small resistance inside the evaporator, so that the cold air can be evenly sent to all parts of the cold storage or processing room, and the air can be sent further.

(2) Overall structural design

Axial flow fan design: it adopts a special fan for low-noise cold storage, and its blades are made of aluminum alloy plate. The blade shape adopts a large chord length, outer width and inner narrow, forward leaning and backward bending high-efficiency new blade shape (the design of this blade shape has won the National Invention Award). It adopts a moisture-proof and waterproof special sealed motor, with a waterproof grade of IP55. The motor and impeller are directly driven, with high operation efficiency, uniform air supply, low noise, low power consumption, low vibration, reliable operation Long service life.

Design of water tray: when used in partition room, packaging room and other occasions, the temperature is high (8-15 ℃), and the appearance of water tray

The surface is easy to frost due to the large temperature difference between the inside and outside, so the structural design to prevent frost is specially considered in the design, that is, polyurethane is used as the insulation interlayer outside the water pan, and then the steel plate is pasted outside.

Technical requirements for fluorine cooling fan:

The ceiling type air cooler is composed of special fan for cold storage, rectifier section, water spraying section, evaporator, water tray, water baffle and other components. Because the air cooler is placed in cold storage or processing workshop with low temperature and high humidity for a long time, the use environment is very bad. Therefore, the following technical requirements are put forward for the manufacture and material selection of the air cooler:

(1) Motor

The impeller is made of aluminum alloy thin material, the hub is formed by steel plate molding, and the surface is treated by electrostatic spraying. The motor is a joint venture motor, which not only ensures safety and efficiency, but also reasonably allocates the investment cost. Direct connection transmission. Under normal use and applicable environmental conditions, the service life of motor bearings is more than 40000 hours.

(2) Evaporator

Copper tube and aluminum alloy sleeve are used, and the copper tube is red copper tube φ sixteen × 0.5, the aluminum sheet is antirust aluminum plate with a thickness of 0.2mm

(1000 series aluminum alloy plate). Set up a finned tube middle plate support in the length direction of the heat exchange tube, set up a group every 1.5m, and make it of aluminum alloy plate to avoid damage when the heat exchange tube deforms and vibrates. The elbow and pipe end (pipe end and header) are welded by air welding. And conduct 2.5MPa air pressure resistance test without leakage.

Shell design

It is directly made of colored plastic steel plate or stainless steel plate (selected according to customers’ needs), which can fully meet the special requirements of cold storage in low temperature and humidity.

Design of water tray and water retaining plate

In order to improve the anti-corrosion performance, the water tray is made of colored plastic steel plate or stainless steel plate (selected according to the needs of customers). The proper slope and inclination of the water tray is the key to drain the frost flushing water in the water tray. Considering the dripping of water on the elbows at both ends and the water seepage at the inlet and outlet holes of the finned pipes at both ends during water frost flushing, the water pan extends to both sides and all elbows at both ends are included in the length of the water pan.

In addition, when the frost is flushed with water, a water baffle is set on the windward side of the evaporator. The appropriate spacing and angle (45 °) of the water baffle will not only effectively block the splashing water during frost flushing, but also reduce the air inlet resistance and reduce the loss of fan pressure. The water tray and the upper frame are connected by bolts and sealed with gaskets to prevent frost water leakage. In order to reduce the condensation at the bottom of the water pan, polyurethane is used as the insulation layer at the bottom of the water pan, and then stainless steel plate is pasted outside, which can effectively prevent the condensation at the bottom.

Air conditioning equipment

This plan adopts two sets of automatic detection and control systems of gas regulating equipment to control the gas composition in the reservoir area. The equipment is mainly composed of hollow fiber membrane nitrogen generator, carbon dioxide remover, reservoir gas detection and control system, screw air compressor, regulating station, reservoir gas balance valve, reservoir gas balance bag, etc.

3.3ca Series hollow fiber membrane nitrogen generator

CA series nitrogen generator is specially designed for the supporting use of controlled atmosphere storage, which is used to reduce the oxygen content in the controlled atmosphere storage and make the fruit and vegetable products in ideal storage conditions. CA series nitrogen generator adopts hollow fiber membrane group of international famous manufacturer as the main component of air separation, which has the characteristics of large air volume, small volume and long service life. The service life of the filter depends on the cleanliness of the environment, and it is equipped with a series of functions such as regular drainage and pipeline overpressure protection.

The model and quantity of the hollow fiber membrane nitrogen generator supporting the project are 2. Main functions and performance indexes of single equipment:

Nitrogen production (at 95%): 36Nm3/h

Power supply: 220V±10%/50Hz/2kw

Overall dimension: eight hundred × six hundred × 2000 mm

Weight: 193kg

3.4ct series carbon dioxide remover

CT series carbon dioxide remover is mainly used together with nitrogen generator and other controlled atmosphere storage equipment or separately to control the percentage content of carbon dioxide in the controlled atmosphere storage, so that fruit and vegetable products are under ideal storage conditions. The equipment adopts high-quality CO2 adsorbent, which has the characteristics of high absorption efficiency, fast regeneration and long service life. The key components of the equipment are products of international famous manufacturers, so the product has high reliability and long service life, and the performance of the whole machine is in the leading position among similar domestic products. The model of the CO2 remover for your project is:, quantity.

*Main functions and performance indexes of single equipment:

Removal amount: 220kg/24h (at 3% concentration)

Power supply requirements: 380V±10%/50Hz/4kW

Overall dimension: Ф one thousand and eighty × 2200mm

Weight: 780kg

Inlet and outlet pipe diameter: Ф 110mm

3.5 series automatic detection and control system of reservoir gas

The working purpose of the warehouse gas detection and control system is to check and measure the percentage content of CO2 gas and O2 in the controlled atmosphere warehouse, and automatically (or manually) open and close the warehouse sampling valve. And automatically (or manually) control the opening and closing of warehouse valves and removal machines according to the sampling results. Oxygen and carbon dioxide sensors do not need calibration of standard gas, but ordinary atmosphere, which is convenient to use and superior to other products. The model and quantity of the automatic detection and control system for gas storage supporting your project are 2 sets.

The functional performance indexes of the gas storage detection and control system are as follows:

online check and measure the percentage content of O2 and CO2 in the controlled atmosphere warehouse.

touch screen displays, stores and prints the percentage content of O2 and CO2 gas.

set O2 and CO2 control values and time.

control the startup and shutdown (automatic and manual) of carbon dioxide remover.

control the opening and closing of warehouse connecting valves (automatic and manual).

measurement range: O2: 0%~21% CO2:0%~10%

resolution: 0.1%

accuracy: ±0.2%

external power supply: 220V±10%/50Hz/0.2kW

temperature range: 10~35℃

Humidity range: ≤90%RH

display mode: Cabinet touch screen display

size: 1740mm × 650mm × 600mm

multiple machines can form a network and can be equipped with network computers.

3.6 series reservoir gas regulating station

Series gas regulation station is the supporting equipment of gas regulation station. It gathers the pipelines of several warehouses in one place, making them easy for users to use, unified management and beautiful appearance with the nitrogen generator and carbon dioxide remover produced by our company. The regulating station can greatly reduce the time and complexity of on-site construction and better ensure the good air tightness between valve groups.

3.7 humidification device

According to the requirements of customers for the humidity in the warehouse, each cold storage is equipped with a high-precision indoor air humidifier, and the centrifugal humidifier dedicated to the CA warehouse is beautiful and practical. The water mist particles in the balanced humidity field exchange heat with the flowing air to achieve the purpose of humidifying the air.

3.8 Library Board

Pir-100 thick cold storage board is selected for this project, which has the following characteristics:

1) High quality raw materials: raw materials produced by * * * * and * * world famous manufacturers are used to ensure product quality.

2) Stable performance: adopt high-pressure continuous foaming equipment and process to make the batching accuracy of each chemical raw material reach 0.001, ensure sufficient mixing, ensure perfect foaming, and avoid secondary foaming;

3) Green and environment-friendly foaming agent: foaming with fluorine-free stock solution, no CFCs are produced, and the greenhouse effect is

0, no pollution to the environment; See the penny test report.

4) High closed cell rate: the closed cell rate is greater than 97%, which makes the core material have low water absorption and ensures the lasting stability of thermal conductivity;

5) Ultra low thermal conductivity: ≤ 0.021w/ m2 K thermal conductivity;

6) High density core material: polyurethane (PUR) with an average density of 42kg/m3 makes the composite board have higher tensile and compressive strength;

7) Recyclable core material: composite board can be recycled to protect the environment.

4、 Air conditioning cold storage door

The high-density foam is used for one-time molding, and the yellow orange pattern plastic sprayed 0.6mm color steel plate and color steel plate are used for outsourcing. The reverse panel is 3mmpp plate, and 6063-T5 aluminum alloy is used for one-time extrusion molding. The surface coating is made of new electrophoresis treatment high-performance heat insulation flame-retardant polyurethane. The open fire is self extinguishing in 3-5 seconds, and the thermal conductivity: ≤ 0.023w/m.k, and the melting weight ≥ 42kg/m3. Manual pneumatic control valve with internal door opener and tripping function

5: Equipment power

The power of refrigeration equipment, air conditioning equipment, humidification equipment, lighting power and other production equipment are considered in the whole project, and the configured power supply is 380v-415v/3p/50hz (60Hz) ≥ 300kW It can be divided into two incoming lines, and a single power line is copper yjv3*95mm+2.

6: Construction period plan

The main structure is enclosed by single-layer rock wool board of steel structure, and the design and construction time of steel structure is about 2-3 months. The installation time of cold storage is about 3 months, and the construction to use time of the whole project is about 7-8 months.

Note: the above is only the general description of a project. For reference only. Specific project requirements shall be subject to the actual situation. Some parameters in this scheme are empty, and the specific design requirements of specific projects. For customers’ reference.