1、Characteristic

1.1 Insulation

- The bottom plate is assembled by full welding process, which has excellent waterproof and thermal insulation performance.

- There are maintenance and cleaning channels on both sides of the warehouse body, which is convenient for cleaning and maintenance of equipment;

- The reservoir body is provided with a drain outlet, which can drain quickly and not store water;

4 The specially designed sealing strip of the thermal insulation door can effectively block the airflow and prevent the occurrence of cold running.

- Electric heating is embedded in the door frame, and the heating is uniform, ensuring that the thermal insulation door does not freeze and is easy to open.

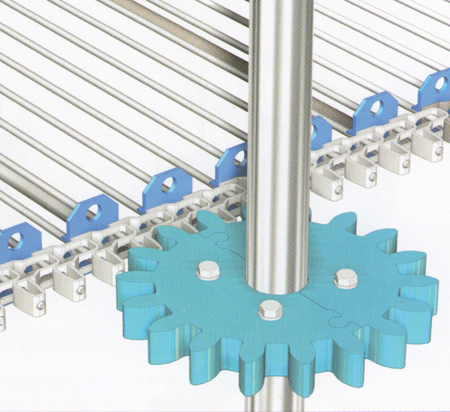

1.2 Conveyor

- The cage-free design is adopted, and the special structure of the mesh belt is in the form of slider buckle, which completely avoids the problem of turning over the belt;

- Due to the cancellation of the cage, the single-spiral low-end purchase and low-end shipment can be realized;

- Adopt multi-layer side drive, stable operation and easy maintenance;

- The drive gear has high strength, no lubrication, and adopts quick-release design for easy replacemen

1.3、Belt

- The mesh belt material is food-grade stainless steel, which is corrosion-resistant, high-strength, and passivated on the outer surface;

- There are sliders with special structure on both sides of the mesh belt, which not only avoids the mesh belt from turning over, but also prevents the product from slipping.

1.4、Air System

1 Adopt stainless steel axial flow fan, fully enclosed moisture-proof and low-temperature resistant motor, low noise and stable operation;

2 The supply and return air is smooth, the freezing effect is good, and the energy saving is efficient.

1.5、Evaporator

- The structure is advanced and reasonable, the flow resistance of the refrigerant in the tube is small, the freezing speed is fast, and the freezing quality is good;

- The method of changing the sheet distance, with the best airflow organization, less frost, and can work continuously and efficiently for a long time;

- The production of fins adopts a one-time molding process, the contact area between the tube and the sheet is large, and the heat transfer coefficient is high;

- The defrosting method adopts the water flushing method, and the water spraying tray spraying water method, the flushing water is more evenly distributed, and the defrosting time is effectively reduced.